Composition of Steel Wire Rope

|

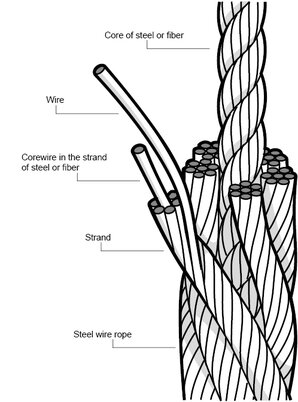

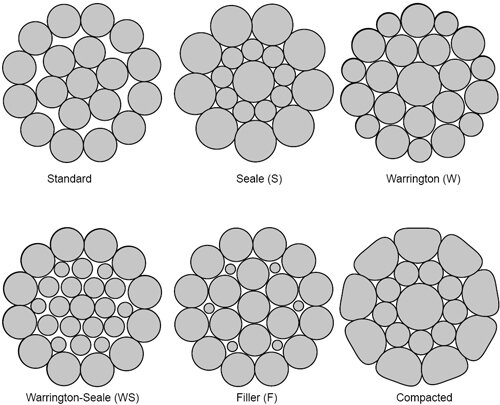

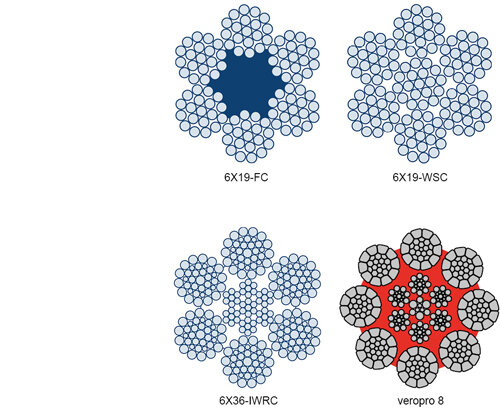

A steel wire rope is crafted by intertwining individual steel wires to form a strand, and several strands are then enclosed around a central core to create the complete rope. The optimal balance between large wires for maximum corrosion resistance and abrasion resistance, and smaller wires for flexibility and ease of handling, is determined by the number and size of wires. The construction of a steel wire rope is denoted by a code, such as 6x36-FC, where 6 represents the number of strands, 36 is the number of wires in each strand, and FC indicates the type of core. |

|

From Raw Rod to Final Rope

|

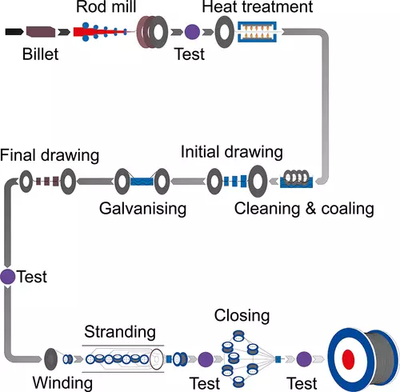

The process of manufacturing a steel wire rope involves various stages, as illustrated. The initial material is wire rod, cold-drawn to different dimensions and strength grades. |

|

| Rope grade | Wire tensile strength grades | Hardness app. | |||||

|---|---|---|---|---|---|---|---|

| EN | API 91 | Min kp/mm2 | Max N/mm2 | Max kp/mm2 | Max N/mm2 | Brinel HB | Rockwell HRC |

| 1570 | PS | 140 | 1370 | 180 | 1770 | 405/425 | 45 |

| 1770 | IPS | 160 | 1570 | 200 | 1960 | 445/470 | 49 |

| 1960 | EIPS | 180 | 1770 | 220 | 2160 | 470/480 | 51 |

| 2160 | EEIPS | 200 | 1960 | 220 | 2160 | 480/500 | 52 |

Strand Lay and Core Selection

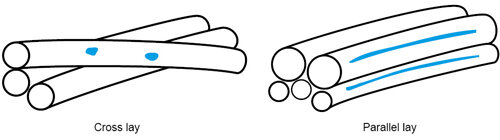

Strand lay refers to the arrangement of wire layers, with cross lay and parallel lay being common. The rope's core, crucial for support, can be made of fiber, steel, or solid plastic. Codes like 6X19-FC signify a fiber core, while -WSC and -IWRC denote single-strand steel and steel wire rope cores, respectively. Some ropes even have a plastic-encapsulated core for increased stability, wear resistance, and reduced corrosion.

|

|

|

|

Rope Lay and Rotation Resistance

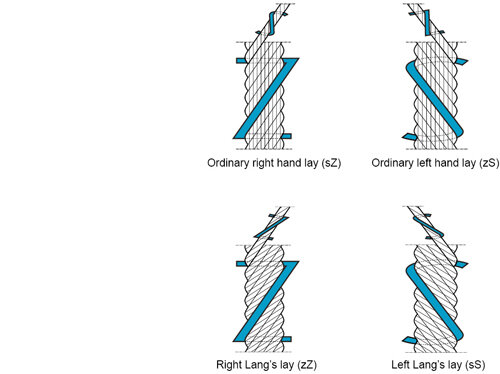

Rope lay describes the direction of wire twist, with options like ordinary hand lay, Lang's lay, right hand lay (zZ), and left hand lay (sS). Rotation-resistant ropes counteract twisting, utilizing layers laid in opposite directions to balance forces.

|

|

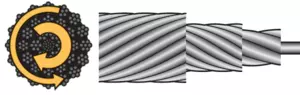

Preforming and Lay Length

Preforming introduces a helical shape to strands, minimizing twisting tendencies and facilitating easier handling. Lay length, representing the helical length of wire or strand, is crucial for the rope's longevity and must be maintained for optimal performance.

|

|

Breaking Load Definitions

Breaking load terms include the minimum breaking load, which is the lowest force at which the rope fails during testing, and the calculated breaking load, determined by the metallic areas of individual wires and tensile strength grades. The latter considers the square of the rope's nominal diameter and incorporates a standard spinning loss factor resulting from strand and wire twisting.